A few nice precision engineering organization photos I identified:

Foster Announces Investment at JW Kane Precision Engineering

Image by DUP Images

Enterprise Minister Arlene Foster today announced that Craigavon organization JW Kane Precision Engineering is undertaking a main investment, that will develop 30 high good quality jobs. The organization currently employs 55 employees manufacturing high precision machined elements for a quantity of higher profile customers which includes Bombardier, Thales, BE Aerospace, GE Hamble and Fokker. Pictured in the course of a tour of the factory are Enterprise Minister Arlene Foster and Damian McArdle, General Manager.

2ID Living Insignia – Historic Photo – 21 May possibly 2009 – US Army Korea – Second Infantry Division

Image by U.S. Army Korea (Historical Image Archive)

imcom.korea.army.mil

2nd ID Warriors kind ‘living insignia’ for 2nd time in division history

By Master Sgt. Michael Pintagro

2nd Infantry Division Public Affairs

Approximately 5,000 Warriors from the 2nd Infantry Division designed a human version of the division’s distinctive Indianhead patch for only the second time in an organizational history dating from World War I Thursday morning (Might 21) at Indianhead Stage Field on Camp Casey, Korea.

A steady drizzle that persisted all through the occasion may possibly have dampened the Warriors’ wet climate gear and dress uniforms but it didn’t dampen the Soldiers’ resolve to take part in an historic event.

Organizers placed the initial human elements of the division patch about six a.m. and continued to build the insignia throughout the early morning, adding Warriors to the massive formation as they marched onto the field as firms, platoons and detachments. Different dress uniforms replicated the insignia color scheme.

The insignia was built from the middle out, with the most intricate portions of the pattern established initial and the masses of Soldiers replicating the exterior placed final.

The division’s commanding basic, command sergeant significant and senior staff stood at the base of the insignia. About 9:25 the assembled Warriors looked up and a modest army of division photographers – numerous mounted 35 feet higher in mechanical “cherry pickers” – commenced snapping shots.

Maj. Gen. John W. Morgan III, the commanding basic, addressed his Soldiers following the second-of-its sort “photo op” in division history.

“Great job,” he told them. “You are part of history and part of the wonderful 2nd Infantry Division. I’m proud of each and every 1 of you. Thank you for your service to the nation and to this excellent division.”

Warriors of all ranks, roles and profession fields from organizations and installations across the division’s footprint in Korea joined their leaders in the “patch.”

According to 2nd Lt. Michael Nuclo, the division engineer operations officer and a important event organizer, leaders made a conscious effort to contain all division units and ranks. “We’ll have Soldiers from each important division hub,” he mentioned ahead of the occasion. “They’re coming from (camps) Hovey, Casey, Camp Red Cloud, Humphrey and K-16.”

Participants expressed enthusiasm for the chance to play a exclusive function in division history.

“When I initial got to Korea they took us to the 2nd ID Museum and showed us the original patch image and stated if we had been right here extended enough we may possibly get a possibility to recreate it,” mentioned Pfc. Isaac Buckman of Firm F, 333rd Target Acquisition Battery, 210th Fires Brigade. “I believed that was really cool, and it’s wonderful that I truly had an opportunity to do it.”

“This will go down in history and will usually be remembered,” added Pvt. Jeremiah Heard of Battery E, 143rd Air Defense Artillery, 210th Fires Brigade. Other Soldiers, he predicted, “will love it and they will wish they could do it just the exact same way that we did.”

Occasion organizers seemed equally inspired by their achievement and relieved it came off with no a hitch.

“This was a deliberate operation like almost everything else we do in this division,” mentioned Lt. Col. Michael Anastasia, the division G-3 (operations officer) and the primary figure in the arranging and execution of the living insignia. “The event was meticulously planned and executed precisely according to that strategy.”

“Everything went really properly,” stated Lt. Col. Leroy Sharpe, the division engineer. “We knew it was going to rain and we planned for it. I’m glad it all came together so well. It was an honor and privilege to be part of history nowadays.”

“I feel it went very effectively,” added Sgt. 1st Class Kyle Roberts, the NCOIC of the division engineer shop. “It feels fairly very good to be portion of an event like this that hopefully will final yet another 84 years.”

The ceremony recreated an occasion carried out 84 years ago at Fort Sam Houston, Texas, which served as division headquarters during the period between the Planet Wars.

“It’s the first time this has been accomplished because 1925,” said William M. Alexander, the 2nd ID museum director and division historian. Organizational pride, heritage and esprit de corps, the retired Army colonel added, motivated both “living insignia” ceremonies.

“Living insignia” formations, Alexander noted, “were broadly popular during the ‘20s – that was probably the higher point of their popularity. Maj. Gen. Morgan had the vision to do this again.”

Alexander said he plans to display the new living insignia photo alongside the 1925 image in the museum foyer.

Occasion organizers confronted daunting engineering, mechanical and logistical challenges. Conducting a five,000-Soldier formation, with all its inherent transportation and scheduling difficulties, represents a important feat in itself. Occasion and unit leaders worked tirelessly to ensure consistency in uniform and precision in placement.

Division engineers faced a especially daunting job: figuring out and implementing the proper configuration and dimensions. This essential engineers to establish models projecting the most likely look of the Soldiers from a vantage point 35 feet high and to the front of the formation, and arranging five,000 Warriors in accordance with that vision.

“We utilised personal computer models – there are mathematical equations we utilized primarily based on the patch design and adjusting for the slope of the angle from 35 feet,” Nuclo stated.

“For all our technological benefits I’m not certain what we did was a lot diverse from what they did in 1925,” he added with a smile. “That was a generation of Americans that constructed a lot of amazing things.”

Organizers and observers described the present as an excellent time for the division to recreate the insignia.

“Service on the Korean Peninsula is so crucial a part of the division’s heritage it is only suitable they do this on the peninsula,” Alexander said. “The division suffered the highest quantity and proportion of casualties throughout the war and its members received the highest quantity of awards. More than half of the division’s service has been in Korea. It is due to that Korean War legacy Gen. Douglas MacArthur stated, ‘No division I’ve ever commanded is better than the 2nd ID.’”

“This is a time in the history of the division when the camaraderie and esprit de corps have never ever been larger,” Anastasia said. “In my 21 years of service I’ve in no way been component of an organization with such a spirit of brotherhood, so this was an excellent time to take the image.”

Nuclo drew an historical parallel amongst the generations of Warriors pictured in the past and present living insignia photographs.

“The older guys in that image would have served in Globe War I, and most of the younger guys would serve later in Planet War II,” Nuclo stated of the 1925 photo. “So you had a exclusive moment when most of the participants served in one particular of the two greatest wars of their era. Now our Soldiers are either on their way from or eventually going to Iraq or Afghanistan – the two wars of our era.”

For more info about the U.S. Army in Korea pay a visit to us on the web at imcom.korea.army.mil

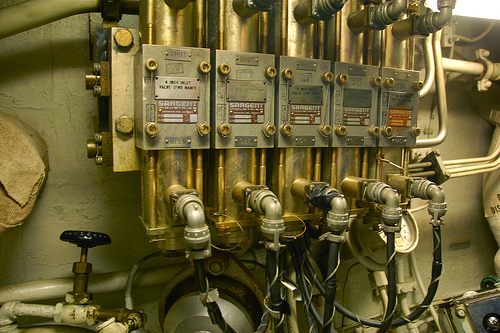

USS Albacore AGSS-569: Sargent Industries valves in the engine room

Image by Chris Devers

I’m guessing these valves had anything to do with setting the depth, maybe?

It looks like Sargent Industries is nevertheless about. Pasting from their corporate history website:

1950s

Sargent delivered a lot more than one-half million precision force handle components for the country’s leading airframe, automotive, marine, missile, metalworking and petroleum industries.

1952

Sargent delivered a exclusive line of marine valves and actuators for nuclear powered U.S. Navy submarines. The company’s innovation and engineering skills persuaded the Navy to accept lightweight aluminum elements to replace the standard steel elements.

1960

Sargent Loved ones sold Sargent Engineering Corporation in 1960 to A.J. Industries, owner of Fletcher Industries. Sargent became known as Sargent-Fletcher with facilities in Huntington Park and El Monte, California.

1965

Electrada Corporation purchased the Huntington Park operation and renamed the business Sargent Industries to reflect its changing solution lines from electrical and electronic to proprietary precision mechanical products.

1969

Sargent started creating its essential quiet valve technology for the U.S. Navy submarine program. At the time, the government was concerned about Navy submarines emitting a sonic "signature" when getting hunted, and it turned to Sargent and other manufacturers to make the quietest feasible marine valves to raise and decrease torpedoes into tubes for deployment.

Sargent earned the coveted contract to begin engineering function for a prototype hydraulic handle valve on the Trident and SSN-688 Class nuclear powered submarines. Thanks to its efforts, the U.S. Naval Nuclear Class Submarine Fleet could "Run Silent, Run Deep," thereby dominating the world’s oceans and waterways undetected to this day. These days, Sargent is the only provider of quiet hydraulic handle valves to the U.S. Navy and its reinvigorated Seawolf-class submarine system.