Precision CNC Milling

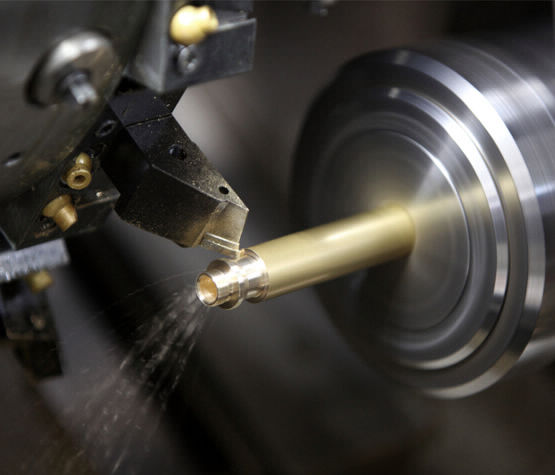

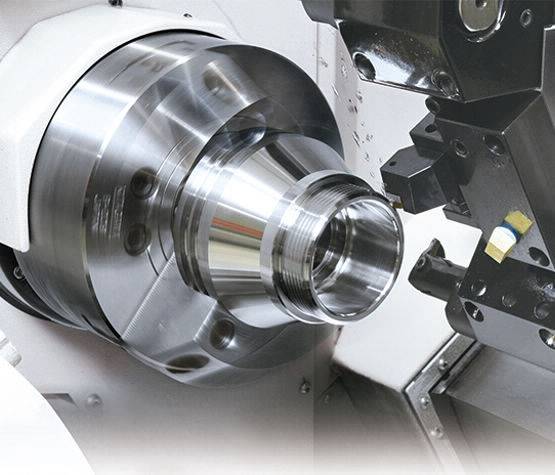

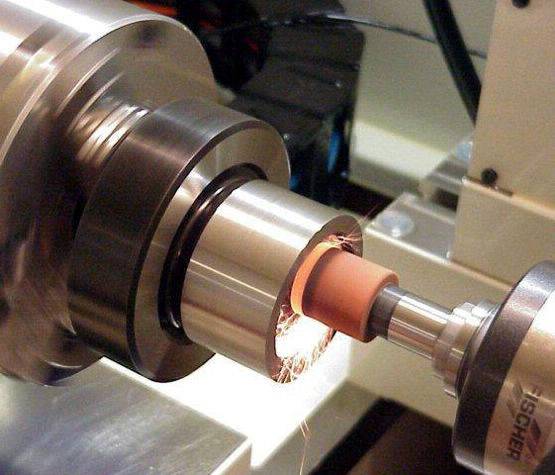

CNC milling has the most efficient ability to remove material from all dimensions to obtain the required part shape at a short time. Due to great efficiency and high cost-performance, CNC milling has grown into be the most popular high precision CNC machining service in China in recent 10 years.

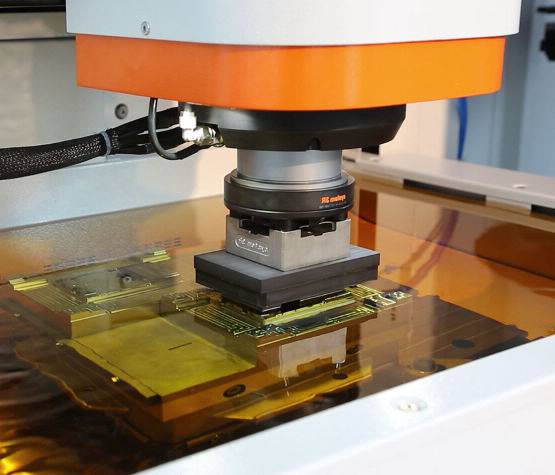

As one of the leading CNC machining China companies, we have full milling capabilities for wide range of requirements, including 3 axis milling, 4 axis turning milling, 5 axis complex machining, high speed milling, swiss machining, horizontal or vertical milling, micro machining, custom milling, etc.