Check out these swiss screw machining images:

Image from page 530 of “Knight’s American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, general technological vocabulary ; and digest of mechanical appliances in science and the ar

Image by Internet Archive Book Images

Identifier: knightsamericanm02knig

Title: Knight’s American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, general technological vocabulary ; and digest of mechanical appliances in science and the arts

Year: 1882 (1880s)

Authors: Knight, Edward H. (Edward Henry), 1824-1883

Subjects: Industrial arts Mechanical engineering

Publisher: Boston : Houghton, Mifflin and Company

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

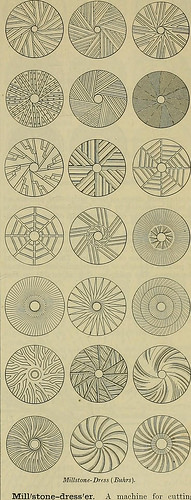

er the face is divided upinto a number of sectors, each of which is known asa qttarter, and has its own set of furrows. The ad-vance edge of a furiow is the leading edge, the otheris the trailing edge. See Grindinc-mill. The querns of the Keltic and Roman inhabitantsof Britain had notches, forming a dre.is. Fig. 3156 is a collection of views of different mill-stones, which will not be described at length. Theupper examples are quarter dress ; then follow spe-cimens of radial-and-circular dress, then a numberof curved and circular systems. In addition to the features involving direction areothers, such as openings in the bed or runner, form-ing pockets, or for ventilation, or to allow escape offine flour. Natchers patent of 1858 is for rulinglines with a diamond on the land of the stone to giveit a cutting quality. In corn and feed mills with serrated iron plates forgrinding, the dress is diflerent, as shown in Fig. 3157. Many of these plates are frustums of conesor conoids. Fig. 3156.

Text Appearing After Image:

Millstone-dresser. A machine for cuttinggrooves in the griuding-faee of a millstone. In one form of the machine, the lines radiatingfrom the center are made by a tool raised and droppedby a cam and advancing automatically along a radialarm attached to a central axis. A Swiss machine for dressing millstones is shownin Fig. 3158. The frame A has arms b b terminat-ing in feet c, whicli are provided with set screws. Atool-sup)iort S is pivoted to the center of A, and isadjustable by means of sector B, and slides on thearm C of the frame. Two disks at A carry diamonds MILLSTONE-DRESSER. 1444 MILLSTONE-PICK.

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Image from page 918 of “Modern mechanism, exhibiting the latest progress in machines, motors, and the transmission of power, being a supplementary volume to Appletons’ cyclopaedia of applied mechanics” (1892)

Image by Internet Archive Book Images

Identifier: modernmechanisme00benj

Title: Modern mechanism, exhibiting the latest progress in machines, motors, and the transmission of power, being a supplementary volume to Appletons’ cyclopaedia of applied mechanics

Year: 1892 (1890s)

Authors: Benjamin, Park, 1849-1922

Subjects: Mechanical engineering

Publisher: New York, D. Appleton

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

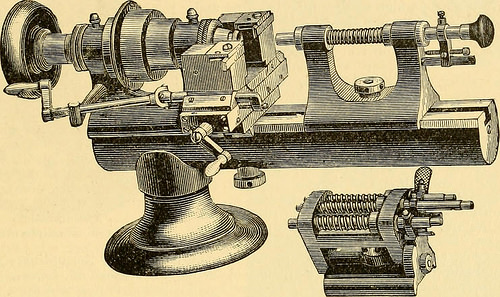

3.—Upright drill. WATCHES AND CLOCKS. 887 spindles, to be used when it is desired to cut different lengths of screws without changingthe tail stock. . Stem-winding Mec7ianis7n.—Although the manufacture ot key-winding watches has beendiscontinued entirely, find only stem-winding watches are now made, these attachments arestill much in demand, in connection with American watches such as the Waltham, Elgin,Hampden, Illinois, Roekford, ( ornell, Howard, etc. English, Swiss, and other foreignwatches, being largely made by hand instead of machinery, the parts are not interchange-able, and consequently cannot be converted ordinarily by the same devices. A novel stem-winding attachment for watches has been devised by Mr. Henry Abbott, ofNew York City. It is designed to be applied to key-winding watches already in use, so as

Text Appearing After Image:

Fio. 4.—Gesswein screw-cutting machine. to convert them into stem-winders. The attachment is manufactured by the same kind ofmachinery and in the same manner as stem-winding watches, and when properly fitted, thewatch is to all external appearances, and to all intents and purposes, the same as if madeoriginally as a stem-winder. Fig. 5 shows the attachment itself, and Fig. 6 presents it combined with a Waltham movement. The pendant of the watch is usually removed, and one suitable for the new winding stem and crown substituted. The stem projects with-in the case, and carries on its end a small beveled winding pinion, which meshes with a crown wheel pivoted between two plates, one called the main plate and the other the yoke ; the upper or yoke plate is of an elongated shape, and mounted so that it may be rocked upon a pivot. On either side of the central screw or pivot the yoke carries pinions or gear wheels, both meshing with the crown wheel, one (called the inter-mediate winding w

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Image from page 917 of “Modern mechanism, exhibiting the latest progress in machines, motors, and the transmission of power, being a supplementary volume to Appletons’ cyclopaedia of applied mechanics” (1892)

Image by Internet Archive Book Images

Identifier: modernmechanisme00benj

Title: Modern mechanism, exhibiting the latest progress in machines, motors, and the transmission of power, being a supplementary volume to Appletons’ cyclopaedia of applied mechanics

Year: 1892 (1890s)

Authors: Benjamin, Park, 1849-1922

Subjects: Mechanical engineering

Publisher: New York, D. Appleton

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

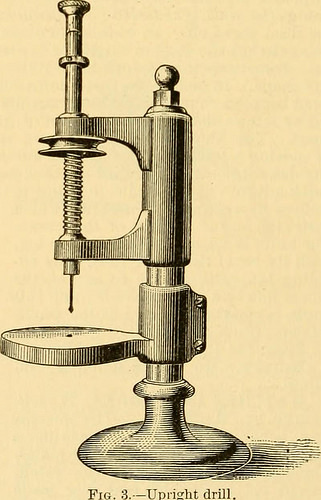

yaccurately to a length from shoulder to shoulder,and also in diameter. The turned staffs andpivots are then hardened, and after hardening,are ground and finished on the wig-wag ma-chine. The form of upright drill which is mostlycalled into use in the manufacture of the severalparts of watches and clocks is that shown in Fig.3. The spring action of the drill stock makes itspecially serviceable for this fine work, and in the drilling of plates, bridges, etc. Fig. 4shows a screw-cutting machine of the Gesswein Co.s make, largely used in watch manu-facture. A wire is fed forward through the chuck, which projects between two movable cut-ting heads, and the tail stock has a horizontal screwed rod which acts as an adjustable stopfor the end of the wire, in determining the length of screw to be cut. One of the slide restsor heads carries the thread-cutting tool, and the other, the cutting-off tool. This figurealso shows a detached view of a tail stock for the same machine, with multiple stop

Text Appearing After Image:

3.—Upright drill. WATCHES AND CLOCKS. 887 spindles, to be used when it is desired to cut different lengths of screws without changingthe tail stock. . Stem-winding Mec7ianis7n.—Although the manufacture ot key-winding watches has beendiscontinued entirely, find only stem-winding watches are now made, these attachments arestill much in demand, in connection with American watches such as the Waltham, Elgin,Hampden, Illinois, Roekford, ( ornell, Howard, etc. English, Swiss, and other foreignwatches, being largely made by hand instead of machinery, the parts are not interchange-able, and consequently cannot be converted ordinarily by the same devices. A novel stem-winding attachment for watches has been devised by Mr. Henry Abbott, ofNew York City. It is designed to be applied to key-winding watches already in use, so as

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.