A subset is utilized by cnc precision machining laser carving parts china to perform subsetting or chamfering procedure on existing openings. Rates for subsetting are ordinarily about 25% of those pre-owned when boring a similar material. Feeds for subsetting are typically light, similarly as while counterboring or spotfacing, as a result of the huge measure of surface contact between the instrument and the workpiece.

Feed profundity sum for a subset relies upon the point of the apparatus, the current opening size, and the ideal subset (or chamfer) measurement. When utilizing a 90-degree subset, feed profundity can be discovered utilizing the accompanying equation.

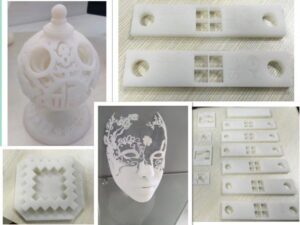

Precision machined digital camera components manufacturers ilustrates this idea and shows varieties of this recipe for various subset points.

A subset will focus itself in a current opening, so the workpiece or tight clamp is ordinarily permitted to coast on the drill press table as opposed to being firmly clasped. Rather, a positive stop is clipped to the worktable to keep the tight clamp or workpiece from turning. To chamfer or subset an opening, follow these means.

- Mount the device in the shaft.

- Calculate and set shaft RPM.

- Set the profundity stop so the instrument is inside around 1/32″ of contacting the edge of the current opening.

- Adjust the profundity stop in little additions of about 0.001 “to 0.003” until the subset contacts the edge of the current opening.

- Adjust the profundity stop to accomplish the necessary profundity.

- While subsetting, the tight clamp (or workpiece if sufficiently enormous to be set legitimately on the table) will move somewhat in a little round movement. This is simply the instrument consistently focusing in the gap and is ordinary.

China metal custom 4 axis cnc machining high precision micro spare parts manufacturers shows a subsetting activity and legitimate situation of a table stop to forestall tight clamp development.

TAPPING

The drill press can likewise be utilized to appropriately adjust taps, taking out the requirement for utilizing a square as when hand tapping. In the event that the workpiece has been moved between the penetrating and tapping activity, the opening can be realigned with the axle utilizing a middle point mounted in the axle, as china steel cnc turned component manufacturers.

Brace the tight clamp or workpiece safely to the table before tapping to keep the work from moving out of position. Subsequent to making sure about the workpiece, follow these means.

- Mount the middle point in an axle mounted throw. This middle point fits in an opening in the head of the tap or in the rear of a tap wrench/handle.

- Mount the tap in a tap wrench/handle.

- Place the tap in the head of the drilled opening.

- Lower the plume so the tip of the tap place is in debt in the tap or tap wrench /handle.

- If utilizing a spring-stacked focus, carry the middle into contact with the tap or wrench/handle by bringing down the plume until the spring is packed. Lock the plume in position with the plume lock.

- If utilizing a strong tap community, one hand must apply light strain to the plume feed handle to keep the tap adjusted while turning the tap with the other hand, as appeared in china high-precision tooling suppliers.

- Turn the tap around each half to one full turn in turn.

- After each forward movement, back the tap out one half turn before proceeding. This helps break the chip being shaped as it cuts. Not backing the tap up will frequently make the tap tie in the opening and break.

- This article is from http://www.cncmachinings.com