Nowadays, we can rely on CNC machining to meet consistency and tolerance requirements. This type of requirements can be met with the help of traditional machines. However, precision machining is commonly used in the medical industry as well. Let’s find out how CNC machining is used in the medical industry.

In the field of medicine, we know that there is no room for inaccuracies. Therefore, the importance of medical CNC machining is rising in the field of medicine. Typically, this technology is used for the purpose of conducting research and making the required components.

Innovation, Quality, Consistency

A few decades back, we could use technology to mimic how human joints work. However, with the help of CNC machines, engineers have changed that altogether.

In other words, this process enables precision as far as making artificial parts of the human body is concerned. This is true even if engineers need to to work on medical implants, complex surface design, and geometries. Aside from this, this technology allows for quicker innovations in the field of medicine.

Regardless of the type of parts required, accuracy and consistency are of paramount importance. Today’s medical products have to meet strict quality standards. For example, the success of a surgical operation depends upon the use of the right type of surgical instruments. If the surgical instruments are not well designed, it can create complication during surgery.

In short, the life of a patient in the operation theater depends on the medical instruments and the medical implants.

Hip Replacements.

With Precision machining services in China, experts have made great improvements in hip replacement. Although these surgeries have a high rate of success, traditional methods and replacement parts have some issues.

The hip replacement surgery is quite common these days, but for patients, this procedure is a big deal. The recovery from this procedure is long and painful. Even a small error in the making of a hip replacement part can make the procedure unsuccessful. Even if the procedure is successful, it may cause problems for the patient for years to come.

If you done the right way, precision machining can be helpful in the making of implants of the right size.

Smooth finishes

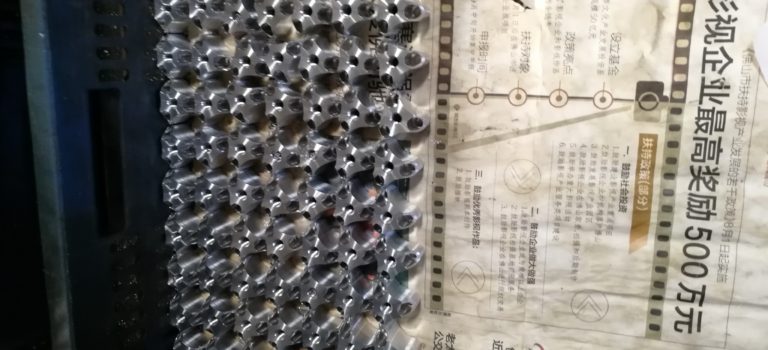

Often, the surface finish of medical components should be smooth and free of defects. This can be achieved in many ways. Experienced and skillful machinists and programmers work together to produce smooth surface finishes with the help of CNC machining equipment.

IN the medical industry, there is a great importance of CNC precision machining. Therefore, manufacturers work day and night in order to improve the consistency and quality of medical devices and tools. This is done in order to help doctors perform different medical procedures with great success.

In short, the advancements in CNC machining has boosted the innovation process in the field of medical devices, tools and implants. That’s why you can see different types of machined components in the medical centers or doctors’ offices.

So, this is how CNC machining is used in the medical industry.

Resource box: This article is originally posted in http://www.cncmachinings.com.